FinCo Fuel will collaborate with Advanced Methanol Rotterdam

GIDARA Energy and the Port of Rotterdam Authority are pleased to announce GIDARA's next advanced biofuel facility in the Netherlands; Advanced Methanol Rotterdam ("AMR"). The plant will convert non-recyclable waste in the Port of Rotterdam into advanced methanol, which will be purchased by FinCo Fuel. The advanced Methanol achieves CO2 emission reductions outlined in the Renewable Energy Directive II (RED II) and the Fit-for-55 frameworks. The renewable fuel will replace fossil fuels, creating significant carbon savings. The Port of Rotterdam Authority has provided a unique site location in the port for this facility.

Advanced Methanol

Advanced methanol is a versatile renewable transportation fuel that, amongst others, can be used in the road transport, marine and aviation sectors, helping these sectors to reduce their carbon emissions and become more sustainable.

One of the main off-takers of the AMR facility will be FinCo Fuel Group, a widespread network of sales companies, including Gulf Bunkering, GoodFuels, Licorne Fuel, Dalergy Group and Gulf Netherlands. Based in the Netherlands, Germany and Switzerland, FinCo is a major player in delivering various low-carbon energy carriers to road and marine clients.

Bart-Willem ten Cate, Manager Renewables Strategy & Development at FinCo Fuel Group: “At FinCo we aim to rapidly increase the share of sustainable, renewable fuels by adding new and innovative products to our portfolio. The bio-methanol that GIDARA Energy is going to produce at the Advanced Methanol Rotterdam facility converts waste stream into a renewable fuel that we can offer to our clients to displace diesel and fuel oil in shipping, both at sea as well as on our rivers. An added benefit of bio-methanol is that it not only reduces CO2 emissions but also improves local air quality.”

Converting non-recyclable waste to renewable fuels

Last year, GIDARA Energy announced Advanced Methanol Amsterdam, a state-of-the-art renewable fuels facility that will serve as a blueprint for AMR. The two facilities will be identical, utilizing GIDARA’s patented High-Temperature Winkler (HTW®) technology, which converts non-recyclable waste to renewable fuels. This technology has been used commercially in four other waste to clean syngas production facilities.

Advanced Methanol Rotterdam will achieve a reduction of 350,000 tons of carbon dioxide equivalents (CO2eq) of greenhouse gas (GHG) emissions per year, producing approximately 90,000 tons of renewable methanol yearly by converting 180,000 tons of local non-recyclable waste that is currently being incinerated.

All side streams of the conversion process at the AMR facility will be put to use so that the CO2 will be captured and led to local greenhouses; bottom product residue will be used for cement production; and other streams like ammonia and salts will be sold and put to use as feed stock for other industries and road salt respectively, creating a circular concept.

The facility is scheduled to start detail engineering and construction in the first half of 2023, when a permit is received, and start production of renewable methanol in 2025.

Wim van der Zande, CEO at GIDARA Energy: "In order to meet the demand for cleaner fuels, GIDARA Energy needs to grow aggressively. This announcement of our Rotterdam facility demonstrates how dedicated we are to taking on the environmental and waste challenges we are all facing. As we have standardized our design and modularised our application, we are able to directly replicate the Amsterdam facility. The location, quality of infrastructure, and access to a broad network of partners were leading factors in deciding the location of our second facility. The cooperation with the Port of Rotterdam makes it possible to develop the integrated product value chain from waste to fuel and other valuable by-products."

Port of Rotterdam CO2 neutral in 2050

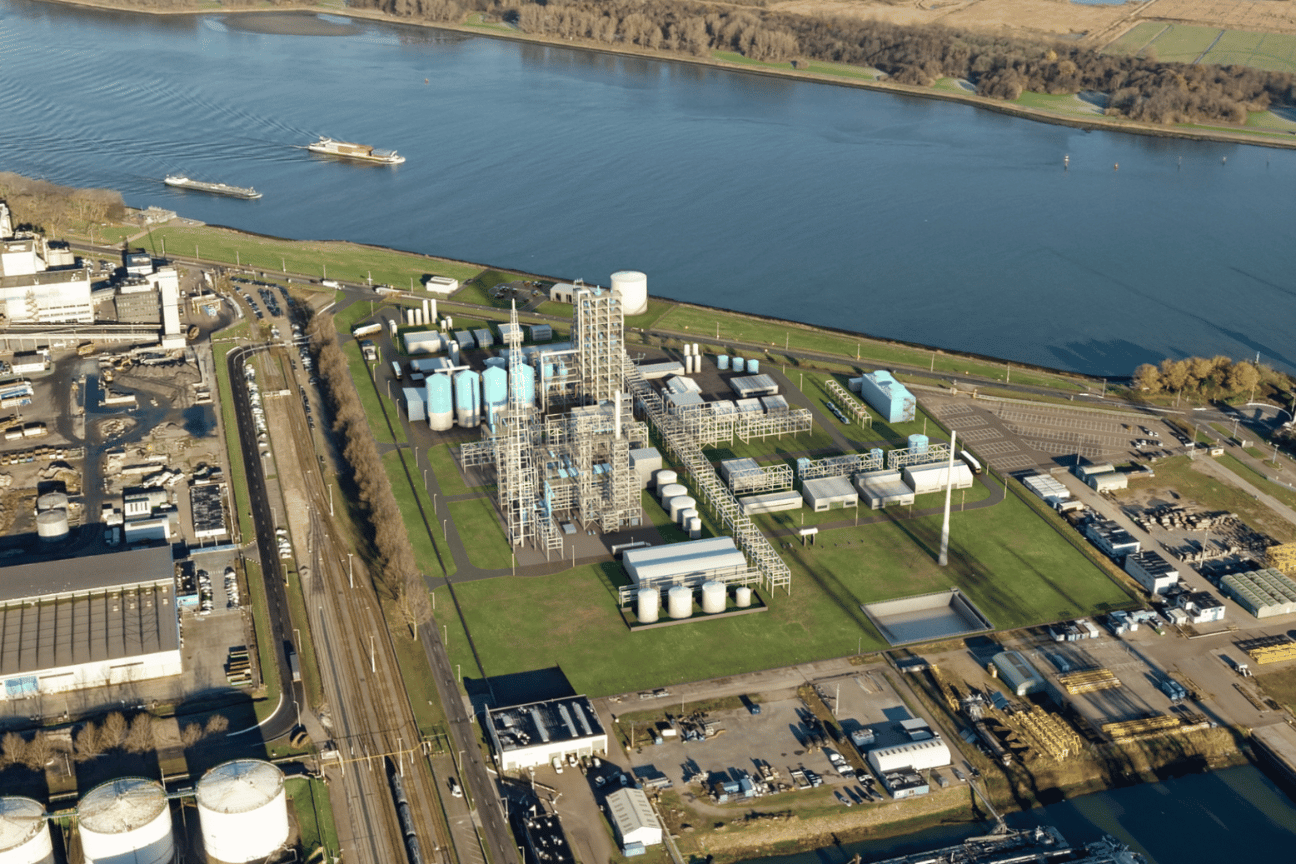

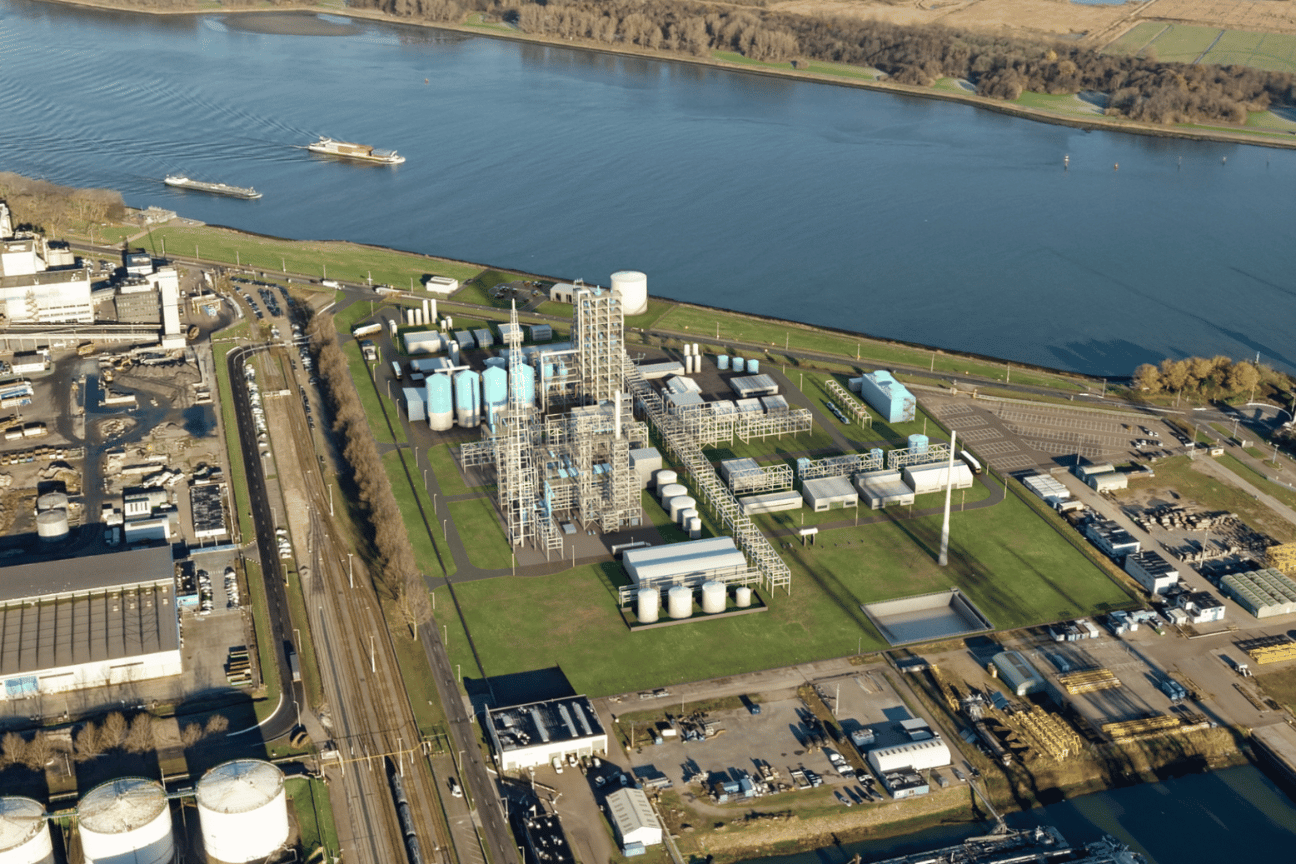

The AMR 8,5 ha site is strategically located at the Torontostraat within the Botlek area of the Port of Rotterdam and is connected to feedstock providers, storage terminals and other companies. The location of the facility is chosen to have an integrated product value chain within short distance.

The Port of Rotterdam’s strategy is to facilitate its existing industries in reducing their carbon footprint and attracting new businesses that fit in the Port Authority’s ambition to be a CO2 neutral port and industrial complex in 2050.

Allard Castelein, CEO at Port of Rotterdam: "We welcome GIDARA Energy’s decision to set up this state-of-the-art facility for the production of sustainable methanol in our port. The Advanced Methanol Rotterdam plant matches very well with our long-term vision for the transition of the industry in the port. This development also shows the importance of clear and reliable governmental policies regarding the energy transition. In this case, regulations regarding the use of sustainable transport fuels stimulate companies to invest in plants like this."